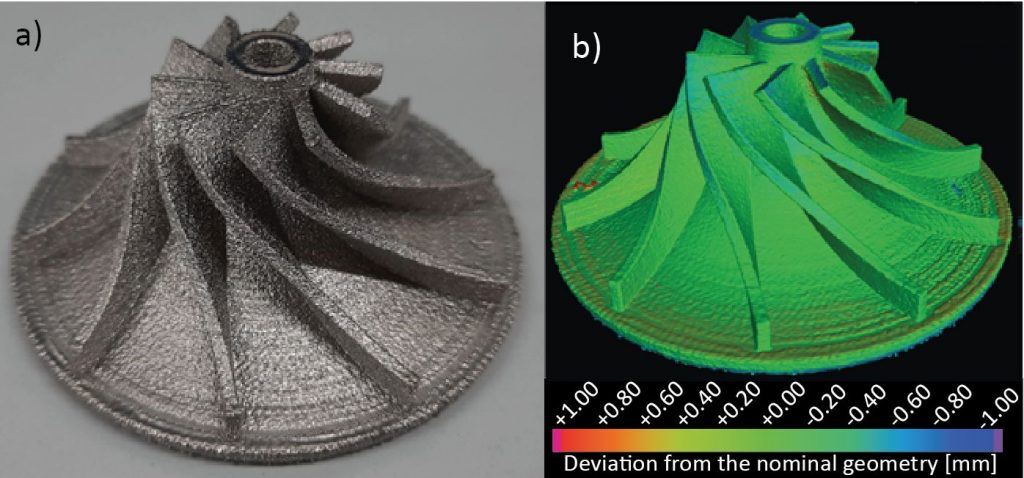

Centrifugal impeller The component is a centrifugal impeller that generally finds application in the automotive field, as the cold side of a turbo compressor or as the rotating component of hydraulic turbopumps. The geometry consists of 10 blades with a thickness of 3 mm on the top of a circular base with a diameter of 80 mm and 3 mm thick. At the centre of the impeller, a through-hole of 6 mm diameter enables the tightening of fasteners. The overall weight is about 200 g. The material adopted is a particular titanium alloy with enhanced thermal properties. The component is produced with an Arcam A2X machine. This machine is based on the electron beam melting (EBM) process, an additive manufacturing process that uses an electron beam to selectively melt metallic powder particles. The process is conducted under vacuum and is a hot process since the temperature inside the build chamber is higher than 700 °C. The density of the material is higher 99.9%. Figure 1 a) is a picture of the produced component while Figure 1 b) represents the dimensional deviation. This analysis was performed using an industrial X-ray computer tomography (CT) scanner.